Choosing the right Ready-Mix Concrete (RMC) for your construction project is a critical decision that can significantly impact the overall success and durability of the structure. According to a recent report by the International Concrete Association, the global RMC market is projected to reach $800 billion by 2025, indicating its pivotal role in modern construction. RMC is favored for its superior quality and time-saving benefits, making it essential for contractors and builders to carefully select the appropriate mix for their specific applications.

As industry expert Dr. Emily Tran, a leading figure in concrete technology, states, “The right RMC selection can enhance the functionality and sustainability of construction projects, optimizing both performance and cost-effectiveness.” With numerous options available, ranging from conventional concrete to specialized mixes designed for unique environmental conditions, understanding the properties and compositions of different RMC types is essential. This guide will explore key considerations to help you navigate the complexities of choosing the right RMC concrete, ensuring your project meets both structural integrity and aesthetic requirements.

Ready-Mix Concrete (RMC) is a crucial element in the construction industry, providing a versatile and convenient solution for various building needs. It is a pre-mixed concrete that is specifically manufactured in a plant and delivered to the construction site in a ready state. According to a report by Global Market Insights, the ready-mix concrete market was valued at over $660 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of around 5% through 2030. This growth underscores the increasing reliance on RMC due to its ability to offer consistent quality, minimize production time, and reduce waste on site.

One of the primary advantages of using RMC is its efficiency in large-scale projects. RMC is designed to meet specific strength and durability requirements based on the project’s needs. The concrete is mixed in a controlled environment, which ensures a uniform product with precise ratios of cement, aggregates, and water. A study by the National Ready Mixed Concrete Association highlighted that utilizing RMC can decrease time spent on-site by over 20%, allowing for streamlined operations and faster project completion. Furthermore, RMC contributes to sustainability efforts, as it can be produced using recycled materials and incorporates additives that enhance its performance while minimizing the environmental footprint.

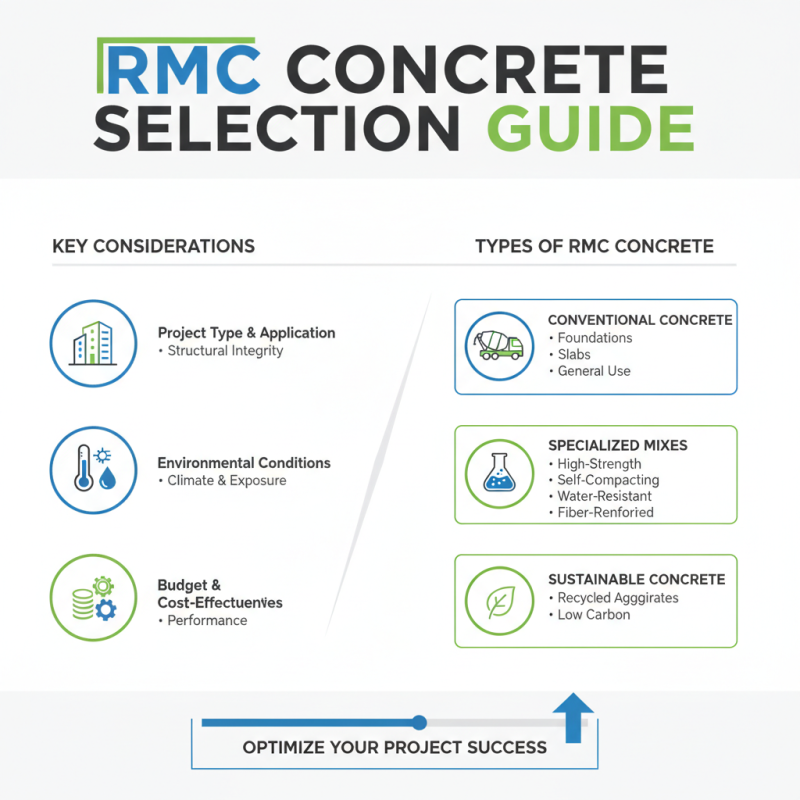

When selecting the right Ready-Mix Concrete (RMC) for your construction project, several factors should be taken into account to ensure optimal results. First and foremost, the intended use of the concrete is crucial. Different projects, whether residential, commercial, or industrial, may require varying strengths and specifications. Understanding the structural requirements, load-bearing capacities, and environmental factors can guide you in choosing the right mix. For instance, a building exposed to harsh weather conditions may need a specially formulated concrete with enhanced durability and resistance to elements.

Another critical factor is the workability of the concrete. This refers to how easily the mix can be manipulated during placement, which is especially important for complex structures or areas with challenging access. Factors such as slump, aggregate size, and admixture types impact workability. Additionally, cost considerations should align with the project budget. While opting for the most economical RMC might be tempting, it's essential to balance cost with quality to avoid potential issues in the future. By evaluating these factors thoroughly, you can ensure that you select the appropriate RMC that meets both your project specifications and budgetary constraints.

When selecting ready-mix concrete (RMC) for construction projects, evaluating the quality of the concrete is paramount. Key characteristics such as compressive strength, workability, durability, and the water-cement ratio play crucial roles in determining the suitability of RMC for specific applications. According to a report by the American Concrete Institute, a compressive strength of 4,000 psi is often deemed standard for residential applications, while infrastructure projects may require higher strengths ranging from 5,000 to 8,000 psi.

Additionally, adhering to industry standards such as ASTM C94, which outlines the specifications for ready-mixed concrete, ensures consistent quality and performance. Important metrics include the aggregate grading and the amount of air entrainment, particularly in areas exposed to freeze-thaw cycles. The National Ready Mixed Concrete Association highlighted that optimal air content can significantly enhance concrete durability in harsh environments, thereby extending the structure's lifespan. By focusing on these quality indicators, construction professionals can make informed decisions that align with project requirements and performance expectations.

When budgeting for Ready-Mixed Concrete (RMC) in your construction project, it is essential to consider a range of factors that can significantly impact costs. First, the pricing of RMC can fluctuate based on local market conditions, including the costs of raw materials, labor, and transportation. Therefore, conducting a thorough market analysis and obtaining multiple quotes from suppliers can help you gauge the average price and identify the best value for your project.

Another key factor to consider is the specific grading and mix of concrete required for your project. Different grades have varying composition requirements, which can affect both the durability and cost. For instance, opting for a higher-grade concrete may provide long-term savings through reduced maintenance and increased lifespan but can lead to higher upfront costs. It is also crucial to account for any additional expenses associated with delivery, site preparation, and any specialized equipment needed for mixing or pouring the concrete. By comprehensively addressing these elements, you can create a realistic budget that aligns with both your financial constraints and project specifications.

| Concrete Type | Strength (MPa) | Cost per Cubic Meter ($) | Typical Application |

|---|---|---|---|

| Standard RMC | 25 | 120 | Residential Foundations |

| High Strength RMC | 40 | 150 | Commercial Buildings |

| Eco-friendly RMC | 30 | 135 | Sustainable Projects |

| Water-resistant RMC | 25 | 140 | Wet Environments |

| Self-compacting RMC | 30 | 160 | Complex Shapes |

When selecting a reputable Ready-Mix Concrete (RMC) supplier for your construction project, several key factors should be considered to ensure quality and reliability. According to the World Cement Association, the global RMC market is projected to grow at a CAGR of 6.5% from 2021 to 2026, indicating an increasing demand for quality concrete. Suppliers should be evaluated based on their adherence to industry standards and protocols, such as the American Concrete Institute (ACI) guidelines, which ensure that the concrete meets the necessary strength and durability requirements.

Furthermore, it’s vital to assess the supplier's track record and customer reviews. A study by the National Ready Mixed Concrete Association highlights that 75% of contractors prioritize supplier reliability and service quality when making purchasing decisions. Engaging with previous clients or delving into online testimonials can provide insights into the supplier’s responsiveness, consistency in delivering products on time, and overall customer satisfaction.

Additionally, consider the supplier's capacity to fulfill large volume orders and their ability to customize mixes for specific project needs, which can significantly influence the outcome of your construction endeavor.