When embarking on a construction project, whether it’s paving a driveway, constructing a foundation for a building, or creating an outdoor patio, accurate material estimation is pivotal. One of the most effective tools for achieving precision in these calculations is the concrete base calculator. This user-friendly tool simplifies the complexities involved in determining the quantity of concrete required for your specific project, thereby minimizing waste and ensuring cost-effectiveness.

Using a concrete base calculator not only saves time but also enhances the accuracy of your material estimates. By inputting measurements such as length, width, and depth, you can obtain precise calculations that reflect the true volume of concrete needed. This is particularly crucial in large projects where even small errors can lead to significant financial repercussions. Furthermore, understanding how to properly use this calculator can empower you to make informed decisions and tailor your project specifications to better suit your needs.

In essence, a concrete base calculator is an invaluable resource for anyone involved in construction or renovation projects. Whether you are a seasoned contractor or a DIY enthusiast, mastering this tool is essential for achieving successful outcomes. This guide will provide you with the necessary steps to effectively utilize a concrete base calculator, ensuring your project remains on track and within budget.

Concrete base calculators have become essential tools for professionals and DIY enthusiasts alike, allowing for precise project estimations that can significantly impact project budgets and outcomes. These calculators help determine the amount of concrete needed for a given area, taking into account factors such as depth, length, and width. According to industry reports, accurate estimations can lead to cost savings of up to 15% by preventing over-ordering and reducing waste, which is a common issue in construction projects.

When using a concrete base calculator, it’s vital to consider the type of project you are undertaking. For instance, whether pouring a driveway, slab, or footer can influence the required specifications. An industry study highlighted that incorrect calculations in material estimations not only inflate costs but can also delay project timelines by necessitating additional orders. Thus, leveraging accurate measurements is crucial for maintaining project efficiency.

Tips: Always double-check your dimensions before inputting them into the calculator. It’s also worth keeping in mind local concrete prices and potential fluctuation in material costs, which can affect your overall project budget. Lastly, including a buffer of approximately 10% for unexpected needs can further safeguard against material shortfalls during your project.

When using a concrete base calculator for your project estimations, precise data input is crucial to achieve accurate results. The first key metric to consider is the area that the concrete will cover. This involves measuring the length and width of the space, and calculating the area in square feet or square meters. If the area has irregular shapes, breaking it down into smaller sections can simplify measuring. Properly understanding the area ensures that you don’t overestimate or underestimate the amount of concrete needed.

Another vital metric is the thickness of the concrete layer. Typically, the thickness may vary based on the intended use of the slab – whether for residential driveways, commercial applications, or pathways. For most applications, a thickness of between 4 to 6 inches is common, but certain projects may require different specifications. Finally, the calculator usually asks for the desired yield in cubic yards or cubic meters; making sure you input the correct conversions can further refine your estimation. Gathering accurate input data not only minimizes waste but also helps in budgeting for your project effectively.

| Project Name | Area (sq ft) | Thickness (inches) | Volume (cubic yards) | Estimated Cost ($) |

|---|---|---|---|---|

| Residential Patio | 250 | 4 | 3.08 | $350 |

| Driveway Extension | 400 | 6 | 6.67 | $800 |

| Backyard Slab | 300 | 5 | 5.00 | $600 |

| Commercial Walkway | 600 | 4 | 8.00 | $960 |

| Foundation Base | 1500 | 12 | 50.00 | $6000 |

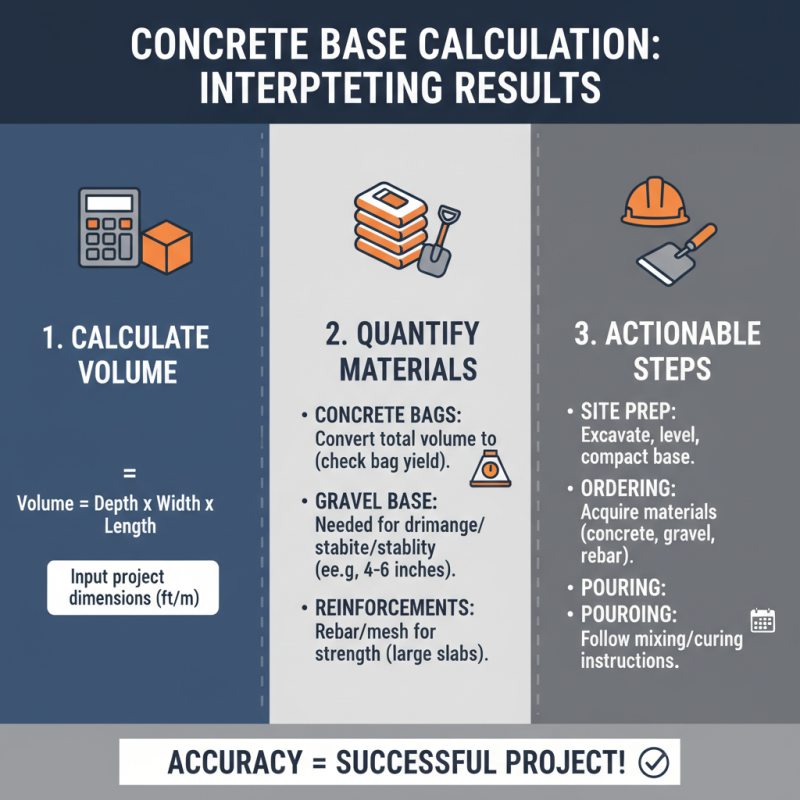

Calculating concrete volume accurately is crucial for any construction project, as it helps ensure that you order the right amount of materials. To begin, you should gather essential measurements, such as the length, width, and depth of the area you’ll be working on. For basic rectangular or square slabs, use the formula: volume = length × width × depth. This will give you the volume in cubic feet or cubic meters. For more complex shapes, such as cylinders or slabs with varying depths, it may be necessary to divide the area into smaller, manageable sections and calculate the volume for each segment before summing them up to get the total.

After obtaining your measurements, you can input them into a concrete base calculator. Most calculators require you to enter the dimensions in a specific unit, so be sure to maintain consistency in your measurements. Once you input the values, the calculator will provide you with the volume needed for your project, typically expressed in cubic yards or cubic meters. It's also worth noting that calculators may include additional features, such as estimations for waste or variations in concrete mix, providing a more comprehensive assessment for your project requirements. By following these steps, you can streamline the estimation process and ensure that your concrete supply aligns perfectly with your project's needs.

When using a concrete base calculator, it’s crucial to avoid common mistakes that can lead to inaccurate project estimations. One significant error is neglecting to account for the thickness of the concrete slab. According to the American Concrete Institute, the recommended thickness for residential driveways is typically 4 inches, while heavier applications may require up to 6 inches. Failing to input the correct thickness can drastically alter the estimated amount of concrete needed, resulting in either a shortage or excess.

Another frequent pitfall is miscalculating the area that needs to be covered. Many users forget to accurately measure the dimensions, especially in irregularly shaped areas. Proper measuring not only includes length and width but also necessitates consideration of any curves or angles. A study by the Portland Cement Association emphasizes that precise measurements are fundamental to achieving an optimal mix design and ensuring the structural integrity of the concrete. Additionally, overlooking factors such as drainage can lead to improper slab installation and future maintenance issues. By being mindful of these common mistakes, users can ensure more accurate material estimations and successful concrete projects.

When using a concrete base calculator, the interpretation of results is crucial for project accuracy. Once the calculator provides the volume of concrete required, it’s essential to understand how to translate this number into actionable steps. Begin by assessing the dimensions of your project site, including depth, width, and length. The calculated volume will guide you in determining how many bags of concrete you'll need to acquire, as well as any additional materials such as gravel or reinforcements that might be required based on the specifics of your project.

Utilizing these results effectively involves cross-referencing them with local material sourcing options and associated costs. Not only should the final calculations align with available materials, but it’s also important to factor in potential waste and overage to ensure that you’re prepared for unexpected needs during the pour. Additionally, understanding how varying climate conditions can affect curing times and the strength of the concrete can alter your overall project timeline. This comprehensive approach to interpreting and utilizing your calculations ensures a smoother workflow and enhances the overall integrity of the finished project.