In the construction industry, accurate cost estimation is crucial for project success, particularly when it comes to calculating material expenses. One of the most essential materials in any building project is concrete. According to a recent report by the National Ready Mixed Concrete Association, nearly 80% of all construction projects in the United States involve concrete in some form. This statistic underscores the importance of precise budgeting and planning. To aid in achieving accurate estimations, professionals often turn to tools like the "concrete quote calculator," which provides a streamlined method for determining costs based on various project parameters.

Expert in concrete cost estimation, Dr. Emily Johnson, emphasizes the value of using a concrete quote calculator. She states, "In an industry where margins can be razor-thin, leveraging technology such as concrete quote calculators not only saves time but reduces the risk of financial discrepancies." This statement highlights the need for accuracy in a field where even minor errors can lead to significant budget overruns. By utilizing a concrete quote calculator, contractors, architects, and homeowners alike can obtain reliable cost projections that reflect current market conditions and material prices, ultimately leading to more successful project outcomes.

Concrete quote calculators are essential tools for anyone looking to accurately estimate the cost of their concrete project. Understanding the basics of how these calculators work can significantly enhance the planning and budgeting phase. At the core of a concrete quote calculator is its ability to factor in various essential components, such as the type of concrete required, the volume needed, and local material costs. Users input specific measurements and parameters related to their project, allowing the calculator to provide a tailored estimate that reflects the unique aspects of the job.

In addition to measuring volume and costs, many concrete quote calculators include options for additional features like reinforcement materials, labor costs, and delivery fees. This enhances the accuracy of the quote, ensuring that homeowners, contractors, and builders receive a comprehensive understanding of their potential expenses. Moreover, some calculators may also help users visualize the amount of concrete needed through 3D models, aiding in more effective planning. Overall, grasping how to utilize these calculators effectively allows for more informed decision-making and can help prevent budget overruns.

| Project Type | Estimated Volume (Cubic Yards) | Cost per Cubic Yard ($) | Total Estimated Cost ($) |

|---|---|---|---|

| Driveway | 10 | 120 | 1,200 |

| Foundation | 20 | 130 | 2,600 |

| Patio | 15 | 115 | 1,725 |

| Sidewalk | 5 | 110 | 550 |

| Pool Deck | 8 | 125 | 1,000 |

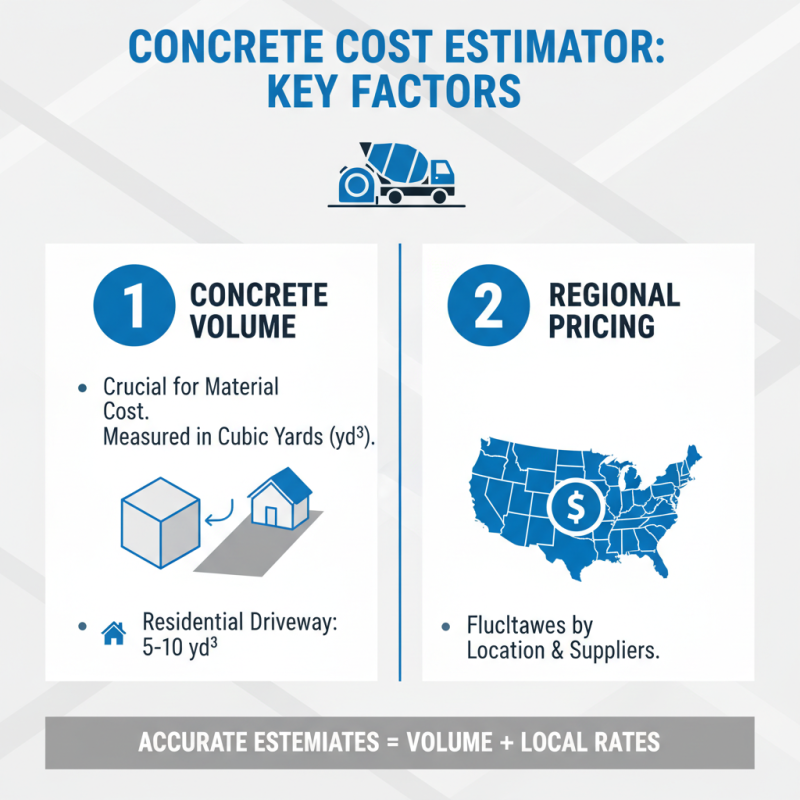

When it comes to accurately estimating concrete costs, several key factors must be meticulously considered. First, understanding the volume of concrete required is crucial; estimates often rely on the cubic yards of concrete needed for the project. According to the National Ready Mixed Concrete Association, a standard residential driveway typically requires about 5 to 10 cubic yards of concrete, depending on its size. This volume calculation is foundational and aids in deriving an accurate estimate of material costs, which can fluctuate based on regional pricing.

Another important factor is the type of concrete mix used for the project. Industry reports indicate that different mixes can vary significantly in price, depending on their specific properties and intended use. For instance, high-strength concrete may be necessary for load-bearing structures and can cost up to 20% more than standard mixes, as documented in the American Concrete Institute’s materials forecasts. Additionally, labor costs, which can comprise over 30% of the total project costs, are impacted by the complexity of the installation. Thus, accurately assessing all these elements—volume, mix type, and labor—enables project managers to leverage a concrete quote calculator effectively for precise cost estimations.

Using a concrete quote calculator can streamline the process of estimating project costs, ensuring that you're prepared with accurate figures from the outset. To begin, gather all necessary information, including the dimensions of the area to be filled and the type of concrete required for the job. Most calculators will require you to input measurements in cubic feet or cubic meters, so be sure to convert your measurements accordingly for the best results.

Once you've entered your measurements into the calculator, review any additional options or settings available. This may include different concrete formulations or additives that may influence the overall cost. After adjusting these parameters as needed, the calculator will provide you with an estimated cost that includes not only the material but also potential delivery fees and labor costs. It's important to remember that while these calculators offer a reliable estimate, consulting with a professional may further refine your understanding of project costs and requirements.

When using a concrete quote calculator for cost estimation, it's crucial to avoid several common pitfalls that can lead to inaccurate budgeting and unexpected expenses. One significant mistake is failing to account for all required materials. Many people focus solely on the concrete quantity, neglecting essential components such as rebar, formwork, and finishing materials. According to a report by the National Ready Mixed Concrete Association, overlooking these additional items can inflate costs by up to 20%, highlighting the importance of a comprehensive approach to estimation.

Another common error is underestimating labor costs. Many DIY enthusiasts tend to underestimate the time and workforce needed for a concrete project. Data from the Bureau of Labor Statistics indicates that labor can constitute approximately 30-50% of the total project cost, especially for larger or more complex jobs. Failing to include adequate labor time for tasks such as preparation, pouring, and curing can result in project delays and budget overruns. Therefore, utilizing the concrete quote calculator effectively requires a thorough understanding of all facets of the project, ensuring that every aspect is accounted for in the final estimate.

When it comes to concrete projects, obtaining accurate quotes from various suppliers is crucial for project budgeting. The construction industry is known for its fluctuating material costs, and concrete is no exception. According to the National Ready Mixed Concrete Association, the average price of ready-mixed concrete in the United States varies by region, ranging from $110 to $150 per cubic yard. This variability makes it essential to compare quotes carefully to avoid unexpected expenses.

When comparing quotes from different suppliers, there are a few key tips to keep in mind. First, ensure that all quotes are for the same specifications, including the type of concrete and any admixtures that may be included. This ensures that you are making a true apples-to-apples comparison. Second, consider the delivery costs, as transportation can significantly affect the overall price. According to a report by IBISWorld, delivery expenses can account for up to 10-15% of the total cost, depending on the distance from the supplier to the job site. Lastly, check the supplier's reputation and reliability. Industry reports often highlight that lower-priced options may not always meet quality standards, leading to additional costs down the line due to potential project delays or rework.

Incorporating these tips while utilizing a concrete quote calculator can lead to more informed decisions. Spending the time to gather and analyze multiple quotes not only helps in securing better rates but also ensures that the chosen supplier meets project demands without compromising on quality.