Pre mix concrete is a pivotal material in modern construction. It provides durability and strength, ensuring structures can withstand time and elements. According to a report from the Global Research Institute, the pre mix concrete market is projected to grow by 5% annually. This growth reflects the increasing demand for efficient building solutions.

Industry expert Dr. Emily Jacobs, a leading voice in construction materials, emphasizes, "Pre mix concrete significantly reduces on-site labor costs and improves project timelines." This efficiency is important for both large-scale projects and smaller developments. Yet, the process involves complexities that require careful consideration. Choosing the right mix and quality standards can be crucial.

While pre mix concrete boasts numerous advantages, imperfections can arise. Issues like inconsistent quality and hardening times can cause delays. There is a need for continuous improvement in production practices. Understanding these challenges leads to better outcomes in construction projects. The role of pre mix concrete in shaping the future of infrastructure cannot be overstated.

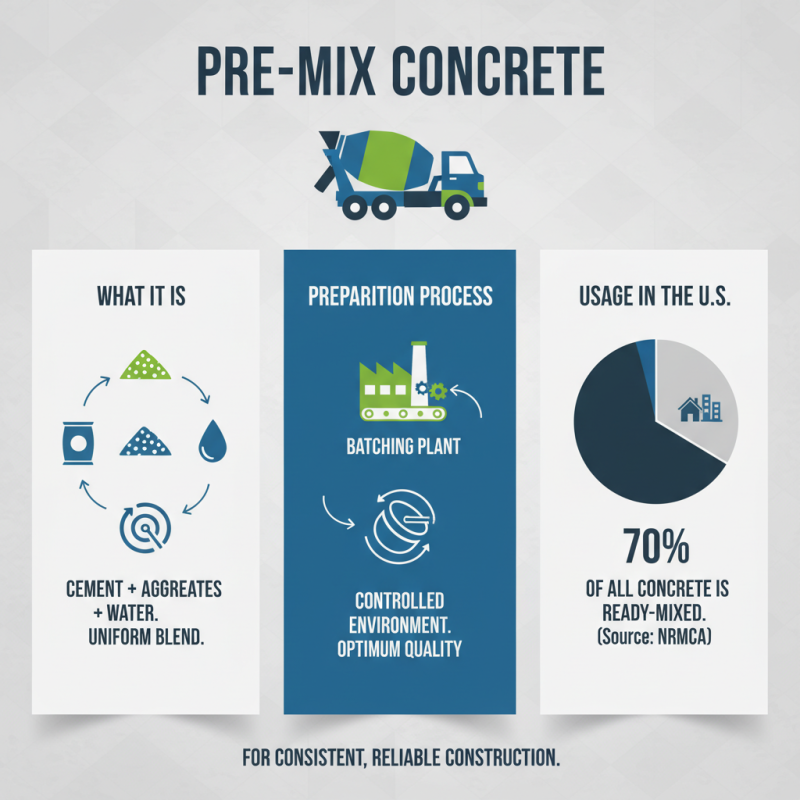

Pre mix concrete, also known as ready-mix concrete, is a mixture made in a controlled environment. This process involves combining ingredients like cement, water, aggregates, and additives. The quality of these materials directly influences the concrete's durability and strength. The American Concrete Institute reports that high-quality concrete can withstand significant pressure, reaching strengths of 4,000 PSI and beyond. Each project can tailor the mix to meet specific requirements.

The composition of pre mix concrete varies widely. Common aggregates can include sand, gravel, or crushed stone, while additives like plasticizers enhance workability. A report from the National Ready Mixed Concrete Association notes that approximately 70% of this concrete is used in various construction projects. However, achieving the right mix can be challenging. Proper ratios are crucial; too much water can weaken the concrete. Miscalculations can lead to failures in structural integrity.

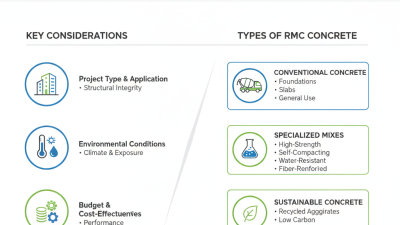

Additionally, environmental factors play a role in how well pre mix concrete performs. Temperature and humidity during mixing and setting are paramount. A study from the Concrete Research journal indicated that extreme conditions might reduce the expected lifespan of concrete. Understanding these nuances is essential for builders. Continuous monitoring and testing can help ascertain the concrete's performance in real-world applications.

Pre mix concrete is a blend of cement, aggregates, and water. It is factory-produced and delivered ready for use. This type of concrete is favored in many construction projects for its convenience and quality control. Several types of pre mix concrete are available, each suited for different applications.

Standard pre mix concrete is commonly used for slabs and sidewalks. It offers good strength for everyday structures. For specialized needs, high-strength concrete is available. This type is perfect for heavy-load areas like bridges. Lightweight concrete is another option. It is used for building components that require less weight, such as high-rise buildings.

Pre-mix concrete, or ready-mix concrete, offers several advantages for construction projects. One major benefit is consistency. It is produced in controlled environments, ensuring uniform quality. This consistency leads to fewer defects and a more reliable end product. Builders can trust that the properties of the concrete will meet project specifications.

Another benefit is time efficiency. Pre-mix concrete can be delivered on-site as needed, streamlining the construction process. This helps reduce delays caused by mixing materials at the site. It also minimizes labor costs since less time is spent on preparation. However, it’s essential to plan deliveries accurately. Timing issues can disrupt workflow and impact project schedules.

Additionally, using pre-mix concrete reduces waste. Builders can order precise quantities, decreasing the chances of leftover materials. Yet, some projects may still require adjustments. If conditions change, the pre-mix might not be ideal for every application. Learning how to adapt to varying site conditions is key for success.

| Dimension | Description |

|---|---|

| Definition | Pre mix concrete is a ready-to-use concrete mixture that is batched and mixed at a central location before transportation to the construction site. |

| Components | Typically consists of cement, aggregates (sand and gravel), water, and admixtures. |

| Usage | Used in various construction applications, including residential, commercial, and infrastructure projects. |

| Benefits | Consistent quality, reduced labor costs, faster construction times, and minimal waste. |

| Environmental Impact | Sustainable option as it can utilize recycled materials and reduce overall carbon footprint. |

| Types | Includes normal strength concrete, high-strength concrete, and specialty concrete mixes. |

| Delivery Methods | Delivered via truck-mounted mixers, ensuring quality and workability at the site. |

Pre Mix Concrete is a mixture of cement, aggregates, and water prepared in a controlled environment. The preparation process is key to achieving optimum quality. Typically, the components are mixed in a batching plant. This ensures a uniform blend before delivery. According to the National Ready Mix Concrete Association, about 70% of concrete in the United States is ready mixed.

The mixing process involves precise measurements. Each ingredient must be calibrated according to specific project requirements. Sometimes, the consistency may vary. Poorly adjusted mixtures can lead to structural problems later. Additionally, environmental conditions can affect the setting of the concrete. For instance, high temperatures can cause rapid setting, making it difficult to work with.

Once mixed, the concrete is transported to the site. It's crucial to avoid delays during this phase. The concrete begins to harden quickly. In a report by the American Concrete Institute, it was highlighted that concrete sets within 30-90 minutes after mixing. If not placed promptly, it can compromise the integrity of the final structure. Proper planning and execution are essential, yet they can often be overlooked in rushed projects.

Pre mix concrete is a crucial element in construction. It simplifies mixing and ensures a consistent product. Many contractors prefer it due to its convenience. However, to achieve the best results, specific best practices should be followed on job sites.

One tip involves checking temperature conditions before pouring. Extreme cold or heat can affect the curing process. Reports indicate that temperatures below 40°F can slow setting times. Conversely, high temperatures can lead to rapid evaporation. Always monitor weather conditions.

Another important aspect is the proper mixing ratio. Batch size impacts the integrity of the concrete. Using more water than recommended can weaken the mix. A study indicated that a 10% increase in water can reduce strength by up to 20%. Stick to the manufacturer's guidelines for the mix.

Proper curing is essential too. During the curing phase, maintain moisture levels to prevent cracking. This typically lasts for at least 7 days. Using curing blankets or sprays can help. If the curing process is neglected, it could lead to future structural issues. Awareness of these aspects is vital for optimal performance.