RMC concrete, or Ready-Mix Concrete, has become a cornerstone of modern construction projects, providing a versatile and efficient solution for various building needs. In 2025, the demand for RMC concrete is expected to grow as more construction companies seek materials that not only meet high performance standards but also adhere to sustainability goals. Understanding the different types of RMC concrete available in the market is essential for selecting the right mix that best aligns with the specific requirements of your project.

Choosing the appropriate RMC concrete involves consideration of several factors, including the structural specifications, environmental conditions, and project timelines. Each type of RMC concrete is formulated to provide unique properties—such as increased durability, faster setting times, or enhanced workability—that cater to diverse applications from residential buildings to massive infrastructure projects. By familiarizing yourself with the characteristics and advantages of various RMC mixes, you can make informed decisions that contribute to the overall success and longevity of your construction endeavors. In the following sections, we will delve deeper into the nuances of RMC concrete and guide you in selecting the best type for your 2025 project.

RMC, or Ready-Mix Concrete, is a pre-mixed form of concrete that is produced in a factory and delivered to construction sites. Its key characteristics include consistent quality, the ability to meet specific project requirements, and time-saving benefits. The concrete is mixed in controlled environments, ensuring that the proportions of materials such as cement, sand, aggregates, and water are accurate. This results in a uniform product that can lead to improved durability and strength, which are essential for any construction project.

One of the standout features of RMC is its versatility. It can be tailored to achieve various properties by adjusting the mix design to fit specific applications, whether it be for residential buildings, roads, or specialized structures. Additionally, because RMC is delivered ready to use, it minimizes the labor required on-site and reduces the risk of wastage. The quick setup time not only expedites construction but also allows for better scheduling and project management. As the demand for efficient and eco-friendly construction solutions grows, RMC's ability to meet diverse needs makes it an increasingly popular choice in the industry.

RMC concrete, or Ready Mixed Concrete, has become a go-to solution in modern construction due to its numerous advantages. One of the main benefits of RMC concrete is its convenience; it is produced in a controlled environment and delivered to the construction site ready for use. This not only saves time but also ensures that the concrete maintains consistent quality throughout the project. With precise mixing ratios and stringent quality checks, RMC allows for superior performance in various applications, from residential buildings to infrastructural projects.

Another key advantage of RMC concrete is its flexibility in meeting specific project requirements. Builders can customize the mix based on the desired strength, durability, and finish, making it suitable for diverse architectural designs. Additionally, using RMC reduces labor costs and on-site clutter since it eliminates the need for on-site mixing, leading to a cleaner and safer working environment. This efficiency, coupled with the reduced risk of human error, makes RMC concrete a smart choice for construction projects aiming for both speed and quality.

RMC (Ready-Mix Concrete) is a versatile building material that comes in various types tailored to specific applications. The most common types include standard RMC, designed for general construction purposes, and high-strength RMC, which is ideal for load-bearing structures and heavy-duty applications.

Standard RMC is often used for residential projects, such as sidewalks, driveways, and foundations, where basic structural integrity and durability are required. It is easy to work with and can be poured into molds to create various shapes.

On the other hand, high-strength RMC is formulated with additives that enhance its durability and compressive strength, making it suitable for skyscrapers, bridges, and other critical infrastructure. This type of concrete withstands high loads and extreme environmental conditions, ensuring longevity and safety in construction projects. Additionally, self-compacting RMC is emerging as a popular choice in complex designs, as it flows into formwork without the need for vibration, allowing for intricate shapes and finishes in architectural applications.

Understanding these different types of RMC can help project managers make informed decisions based on the specific needs of their construction endeavors.

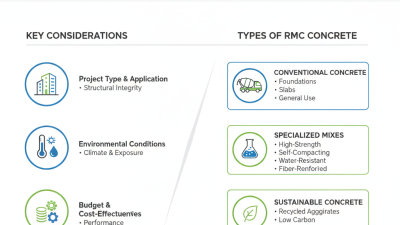

When selecting Ready-Mix Concrete (RMC) for your project, several key factors should be considered to ensure the best results. First and foremost, the strength requirements of your construction should guide your choice. Different projects demand various grades of concrete, ranging from residential to heavy industrial applications. Assess the structural load-bearing specifications and environmental conditions, as they influence the mix design to ensure durability and longevity.

Another important consideration is the workability of the concrete mix. Depending on your project, the pourability and ease of finishing will differ. A highly workable mix is essential for intricate designs or areas with complex mold shapes. Additionally, the projected timeline for your project should be factored into your decision. Ensure that the RMC supplier can meet your deadlines without compromising quality, as timely delivery is crucial for maintaining the integrity of the work. Lastly, consider the environmental impact of your materials; opting for sustainable practices can enhance both the performance and eco-friendliness of your project.

RMC (Ready-Mixed Concrete) is increasingly recognized for its flexibility and efficiency in construction projects. In 2025, choosing the right type of RMC is essential for ensuring durability and performance. According to recent industry reports, the global RMC market is expected to grow significantly, reaching approximately $600 billion by 2025, driven by urbanization and infrastructure developments. To make the most of RMC, it's crucial to understand the specific requirements of your project, including load-bearing capacities, environmental conditions, and curing times.

When ordering RMC, best practices include clearly communicating your project specifications with your supplier. Ensure that you define the mix design to suit your needs, whether it's for residential, commercial, or industrial purposes. Additionally, being aware of the delivery schedule and placement logistics is vital to avoid delays. As noted by industry experts, timely delivery impacts the integrity of the pour, making it imperative to have precise timelines.

Tips: Always check the certifications of your RMC supplier to ensure compliance with industry standards. A reliable provider will offer transparency regarding the materials used, grading, and quality tests, ensuring your project meets all necessary guidelines. Furthermore, consider the use of admixtures to enhance the properties of RMC, such as workability or setting time, which can further tailor the concrete to the demands of your construction site.