In the construction industry, timely concrete truck delivery is pivotal to maintaining project schedules and reducing costs. According to a report by the National Ready Mixed Concrete Association (NRMCA), delays in concrete delivery can extend project timelines by up to 30%, significantly impacting both labor costs and client satisfaction. As projects become increasingly complex and time-sensitive, ensuring the prompt arrival of concrete trucks is essential for the overall efficiency of construction operations.

Effective management of concrete truck delivery involves meticulous planning and coordination. Research indicates that about 15% of construction delays are attributed to logistical challenges, underscoring the need for robust delivery strategies. For instance, optimizing traffic routing and delivery scheduling can minimize downtime and enhance productivity on site. By leveraging technology and real-time tracking systems, contractors can improve communication and ensure that concrete is delivered exactly when needed, thereby preventing costly interruptions and ensuring project success.

Ultimately, understanding the intricacies of concrete truck delivery and implementing best practices can lead to improved operational workflows in construction projects. By prioritizing timely delivery, construction firms can achieve enhanced efficiency, adhere to tight deadlines, and ultimately increase their competitiveness in the market.

Effective planning of concrete delivery schedules is crucial for ensuring that construction projects run smoothly and on time. One of the key strategies is to establish a clear timeline based on project milestones. By identifying when concrete is needed for specific phases of construction, project managers can communicate these timelines to suppliers well in advance. This proactive approach minimizes the risk of delays caused by unavailability of concrete trucks.

Another important tactic involves coordinating with all stakeholders involved in the construction process, including contractors, site managers, and delivery personnel. Regular meetings can help ensure that everyone is aligned on delivery expectations and can address any potential issues before they arise. Additionally, using scheduling tools can enhance visibility and track delivery statuses, making it easier to adapt schedules when necessary. By fostering communication and utilizing effective planning tools, construction teams can significantly improve the timeliness of concrete deliveries, ultimately contributing to the overall success of the project.

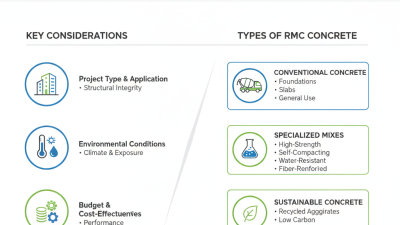

When selecting a concrete supplier for your construction projects, several critical factors should be taken into account to ensure timely delivery and quality service. First and foremost, assess the supplier's reliability by checking their track record and customer reviews. A supplier with a consistent history of meeting deadlines significantly minimizes the risk of delays in your project timeline. Moreover, communication is key; choose a supplier who is responsive and transparent about their processes, ensuring that they can adapt to any last-minute changes in your schedule.

Another essential factor is the range of concrete products offered by the supplier. Different projects may require various types of concrete mixtures, and a capable supplier should be able to cater to these specific needs. Additionally, consider the supplier's logistical capabilities, such as their fleet size and the distance from their batching facility to your site. A supplier with a well-coordinated delivery system is likely to provide more efficient service, reducing waiting times and ensuring that you receive your concrete exactly when you need it. By taking these factors into account, you can secure a supply chain that supports the timely progress of your construction endeavors.

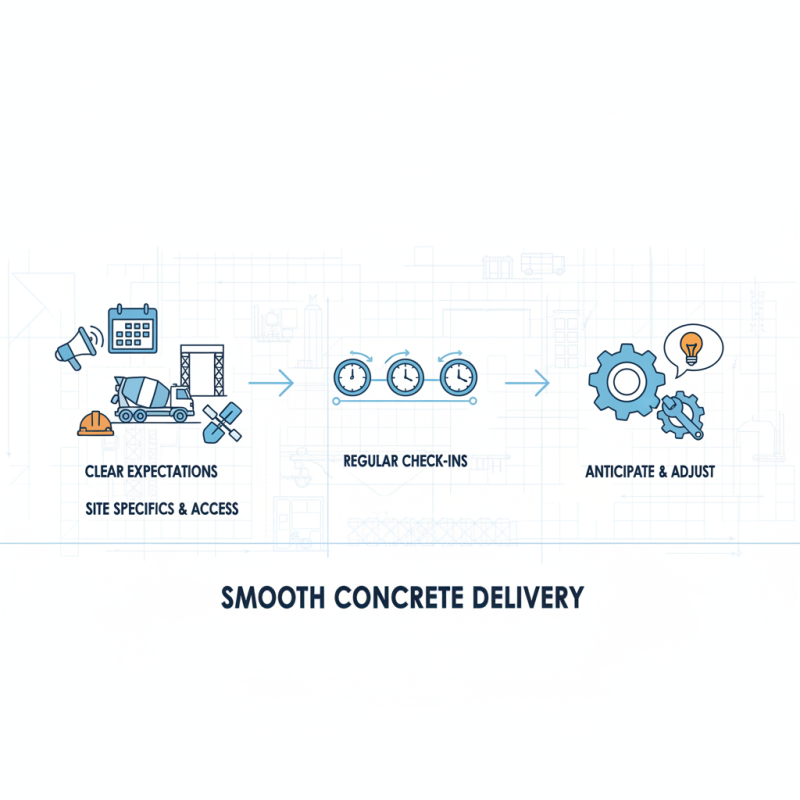

Effective communication is crucial when coordinating concrete truck delivery for construction projects. First and foremost, it's essential to establish clear expectations with the trucking companies regarding delivery timelines and requirements. Communicating the specifics of the job site, including access points and any potential obstacles, helps ensure that the truck can arrive without delays. Regular check-ins leading up to the delivery date can also help anticipate any issues that may arise, allowing for quick adjustments to the schedule if necessary.

In addition to discussing logistical details, maintaining an open line of communication during the delivery process is vital. Designating a point of contact on-site who can relay real-time information to the trucking company can streamline the delivery. This person should be responsible for confirming when the truck is on its way and ensuring that any last-minute changes are communicated promptly. By fostering this collaborative relationship, both parties can work together to handle unforeseen circumstances, minimizing disruptions to the construction timeline.

Tracking and monitoring the delivery progress of concrete trucks is crucial for ensuring the timely completion of construction projects. One effective method is to implement GPS tracking systems installed in the delivery vehicles. This technology allows project managers to receive real-time data on the truck's location, enabling them to anticipate the arrival time and make necessary adjustments to the workflow on-site. By having accurate, up-to-the-minute information, construction teams can reduce downtime and enhance productivity, ensuring that concrete is delivered precisely when needed.

Another valuable approach is to establish a clear communication protocol with the concrete suppliers. Regular updates concerning the status of the delivery can be facilitated through calls, messages, or dedicated project management software. This proactive communication helps identify potential delays early on, allowing teams to adapt their schedules accordingly. Additionally, incorporating scheduling software that integrates with delivery management can provide visual timelines and alerts when trucks are about to arrive. This dual strategy of leveraging technology and fostering communication cultivates a more organized delivery process, ultimately contributing to the success of construction projects.

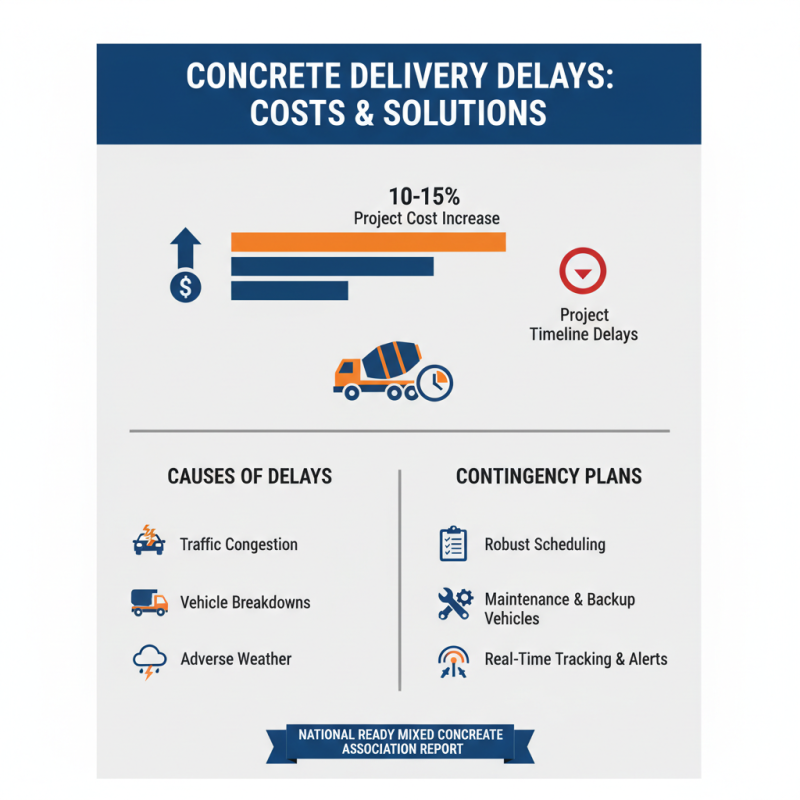

In the construction industry, delays in concrete truck deliveries can significantly impact project timelines and budgets. According to a report by the National Ready Mixed Concrete Association, delivery delays can lead to a 10-15% increase in overall project costs. Ensuring timely deliveries requires implementing robust contingency plans to address unforeseen challenges such as traffic congestion, vehicle breakdowns, or adverse weather conditions.

One effective strategy is to develop a flexible scheduling approach that allows for real-time adjustments based on current conditions. Utilizing GPS tracking for trucks can provide live updates on delivery status, enabling project managers to proactively address potential delays. Furthermore, establishing strong communication channels with suppliers can facilitate quick responses to any issues that arise, thus minimizing the risk of disruption. A comprehensive risk assessment should also be performed at the project’s outset to identify potential delivery challenges and formulate specific contingency measures, ensuring that projects remain on track despite unexpected setbacks.