In the dynamic world of construction, the efficiency of a ready mix concrete plant stands paramount. Noted industry expert Dr. Emily Carter emphasizes, "A well-designed ready mix concrete plant can dramatically improve project timelines." This highlights the critical role such plants play in modern construction solutions.

Ready mix concrete plants streamline operations. They provide precisely measured concrete, reducing material waste and labor costs. These facilities offer flexibility, allowing customization for various project requirements. Yet, many companies struggle to optimize their use of these plants. Issues like scheduling delays and miscommunication can arise.

Moreover, the technology behind a ready mix concrete plant evolves rapidly. Innovations enhance mixing quality and speed. However, not all businesses keep pace with these advancements. Some remain entrenched in outdated methods. This gap can lead to inefficiencies and increased costs. Reflection on these challenges is essential for progress in the concrete industry.

A ready mix concrete plant is essential for modern construction. It includes several key components that enhance efficiency. The batching system is critical. It measures materials accurately, ensuring consistency. This is crucial for durability and strength in concrete. However, errors in measurements can lead to structural issues.

Another vital component is the mixing truck. It transports ready mix concrete to the site. These trucks help maintain the material’s integrity. If they are not properly cleaned, contamination can occur. This can compromise the final product quality. Additionally, the control system plays a pivotal role. It monitors the entire process, from batching to mixing. A malfunctioning control system can create chaos, affecting delivery schedules.

Storage facilities are also important. They house raw materials like cement, sand, and aggregates. Proper storage prevents exposure to moisture, which can damage materials. Yet, many plants overlook maintenance routines. Regular checks can prevent costly downtimes and ensure smooth operations. The layout of the plant should facilitate easy access to all components. Poor design can lead to inefficiencies and delays.

Using ready mix concrete in large-scale projects offers multiple advantages that enhance construction efficiency. One of the key benefits is consistency in quality. Ready mix concrete is mixed under controlled conditions. This reduces the risk of variations in the material, ensuring that every batch meets specific standards. When working on a large-scale project, this uniformity is vital for structural integrity.

Time management also plays a crucial role. Ready mix concrete can be delivered on-site on demand. This feature reduces delays in construction schedules, keeping the project on track. Workers can focus on placement rather than mixing concrete on-site, which can be messy and time-consuming.

Tips: Always verify the production facility. Ensure it's close to your project site. This minimizes transportation time and costs. Also, consider weather conditions when scheduling deliveries. Rain or extreme temperatures can affect the curing process.

While ready mix concrete has many positives, there are challenges. Sometimes, the timing of delivery can be off. This can lead to wasted materials. Additionally, dependence on external suppliers might cause logistical issues. It's essential to have backup plans in place. Planning ensures smooth operations, even if hiccups arise.

Automation is reshaping the

landscape of ready mix concrete production. By integrating advanced technology, plants can achieve higher

efficiency levels. Automated systems monitor and control various processes, reducing human error.

This leads to more consistent mixtures and optimal material use,

a critical factor in construction quality.

However, relying heavily on automation can present challenges.

Technical failures can halt production, causing delays.

Plant operators need training to use these complex systems effectively. It’s essential to balance human oversight with automated processes.

The human touch remains invaluable in troubleshooting unexpected issues.

Embracing automation is not without its flaws. Operators may become too dependent, potentially ignoring manual checks.

This could lead to significant mistakes that impact the final product. A thoughtful approach to automation can enhance efficiency

and safeguard quality. This requires ongoing reflection and adjustment to ensure smooth operations.

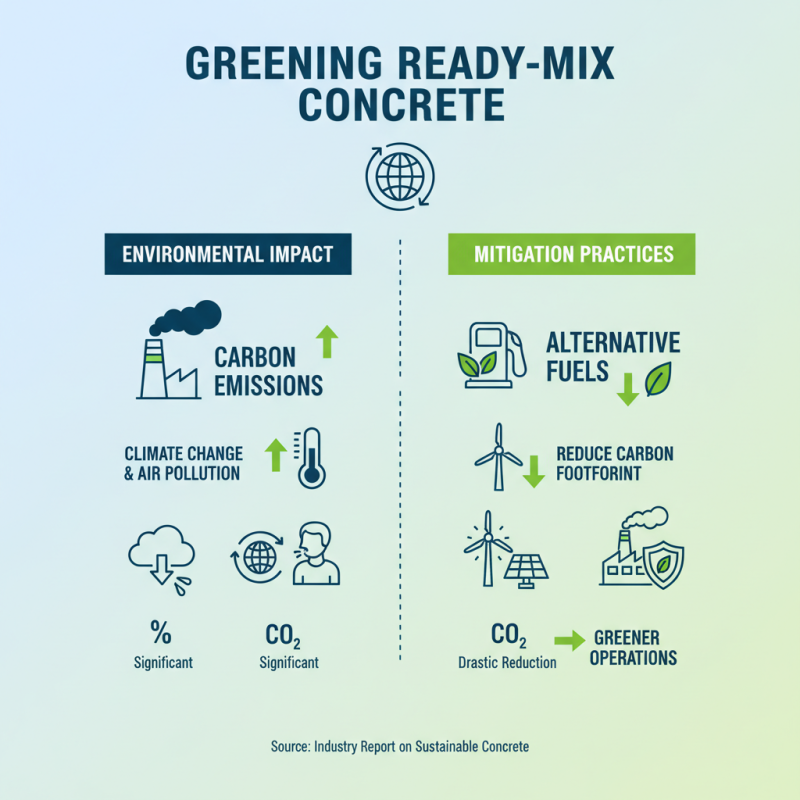

The production of ready mix concrete requires careful attention to environmental impacts. Concrete manufacturing releases significant carbon emissions. These emissions contribute to climate change and air pollution. To mitigate this, plant operators can adopt greener practices. Using alternative fuels can drastically reduce their carbon footprint.

Water usage is another critical factor. Concrete plants often consume vast amounts of water. Excessive water usage can lead to local water shortages. Implementing water recycling systems can help minimize this waste. Additionally, ensuring proper drainage can prevent contamination of local water bodies.

Recycling materials like crushed concrete is gaining popularity. It reduces landfill waste and resource consumption. However, not all facilities have the technology to process these materials effectively. Some operators may hesitate to invest in recycling due to cost concerns. This lack of investment can hinder sustainability efforts in the industry. Balancing productivity and environmental responsibility remains a challenge for many ready mix concrete plants.

The cost-effectiveness of ready mix concrete solutions plays a significant role in construction efficiency. According to industry reports, ready mix concrete reduces labor costs by up to 30%. This is primarily due to the streamlined process of mixing, which eliminates on-site preparation and reduces waste. As per the National Ready Mixed Concrete Association, using this concrete can save approximately $5 to $10 per cubic yard compared to traditional methods.

However, relying heavily on ready mix concrete is not without challenges. Delivery inaccuracies can disrupt construction schedules. A study found that about 10% of projects experienced delays due to late concrete deliveries. This issue highlights the need for better logistics planning. In addition, fluctuating raw material prices can impact overall costs. The cost of cement, for instance, has varied by 15% in the past few years, affecting project budgets significantly.

Furthermore, the initial setup costs of ready mix plants may deter some contractors. While the long-term savings are compelling, the upfront investment can be quite high. A financial analysis suggests that contractors should perform a thorough cost-benefit analysis before committing to a ready mix concrete solution. This ensures that the decision aligns with their project goals while managing potential risks effectively.