In the ever-evolving construction industry, the demand for efficient and reliable materials is paramount. As projects become more complex, professionals are seeking solutions that simplify their workflow without compromising quality. One notable expert in the field, Dr. Emily Hart, a renowned construction materials scientist, emphasizes that "the shift towards ready to use cement mixes is not just a trend, but a necessity in modern construction." This sentiment reflects the growing preference among contractors and DIY enthusiasts alike for convenient, high-quality products that facilitate smoother project execution.

Ready to use cement mixes eliminate the need for extensive preparation and time-consuming mixing processes. They offer a uniform consistency and reliable performance, making them an ideal choice for various applications, from small repairs to large-scale constructions. As we explore the top ready to use cement mixes for your next project, it's essential to consider not only the specific requirements of your task but also the advancements in technology that have led to these innovative solutions. With a focus on efficiency and effectiveness, these products are revolutionizing how we approach construction and paving the way for a new standard in building materials.

When selecting ready-to-use cement mixes for construction projects, it’s crucial to understand the characteristics that denote high quality. A superior cement mix typically demonstrates excellent workability, allowing for easy mixing and application without compromising strength. The mix should have a consistent texture and moisture content to ensure uniform performance throughout the project. Additionally, a good ready-mix should have a well-balanced composition of coarse and fine aggregates, which contributes to its overall stability and robustness.

Another key characteristic is the product's setting time. High-quality cement mixes are designed to meet specific project timelines, ensuring that they cure correctly within the desired time frame without risk of premature drying or weakness. Furthermore, durability is essential; the mix should resist weathering and other environmental stresses over time, ensuring longevity for structures. Finally, effective packaging and storage options can enhance the product's usability, maintaining its readiness for application and preventing contamination. These factors collectively determine the reliability and performance of ready-to-use cement mixes in any construction endeavor.

In 2025, the ready-to-use cement mix market is expanding rapidly, driven by innovations in technology and changing construction practices. Various types of ready-to-use cement mixes are readily available, catering to diverse project requirements. One popular option is standard pre-mixed concrete, which combines aggregate, cement, and water to provide a convenient solution for general construction. According to a report by Smith Research, the demand for pre-mixed concrete is projected to increase by 5% annually due to its time-saving attributes and consistent quality.

Another emerging category is self-leveling mixes, designed for flooring applications. These modern solutions offer excellent flow characteristics, enabling them to spread evenly across surfaces without the need for extensive manual labor. Market analysts from the Global Cement Review highlight how these self-leveling compounds are gaining traction in both residential and commercial projects, projecting a growth rate of 6% from 2023 to 2028. Additionally, specialty mixes with quick-setting properties are becoming increasingly popular among contractors who require efficiency, allowing for faster turnaround times without compromising structural integrity.

Moreover, eco-friendly options are also entering the ready-to-use mix arena. Sustainable materials, including recycled aggregates and less carbon-intensive binders, are becoming a significant part of the conversation around cement mixes. According to a study by Green Building Councils, the market for environmentally-friendly cement mixes is expected to reach $2 billion by 2025, reflecting the industry’s shift towards sustainability while maintaining performance standards. These advancements ensure that the ready-to-use cement mixes available in 2025 will not only meet the demands of various construction needs but also contribute positively to environmental goals.

When selecting a ready-to-use cement mix for your next project, several key factors should guide your decision. First, consider the specific requirements of your project, such as the intended use, the climate conditions, and the load-bearing needs. For instance, if you're working on a foundation that will bear significant weight, you’ll need a high-strength mix. Conversely, for more decorative elements like patios or pathways, a mix designed for aesthetic appeal may take precedence.

Another important factor is the cure time and setting properties of the cement mix. Depending on your timeline, some projects may require faster-setting mixes to meet deadlines, while others might benefit from slower-curing formulations that allow for adjustments and modifications during installation. Additionally, be mindful of the environmental impact of the cement you choose—options with lower carbon footprints or those that incorporate recycled materials can contribute to more sustainable construction practices without compromising performance.

| Mix Name | Type | Strength (MPa) | Setting Time | Applications |

|---|---|---|---|---|

| FastSet Mix | Rapid Setting | 30 | 1-2 hours | Sidewalks, Driveways |

| HighStrength Mix | High Strength | 50 | 3-5 hours | Foundations, Load-bearing |

| Screed Mix | Flooring | 25 | 1-3 hours | Interior Floors, Decks |

| Exposed Aggregate Mix | Decorative | 30 | 2-4 hours | Patios, Walkways |

| Repair Mix | Repair | 20 | 2 hours | Patch Work, Minor Repairs |

In 2025, the market for ready-to-use cement mixes continues to thrive, with several brands emerging as leaders in quality and innovation. According to a recent industry report by Mordor Intelligence, the global ready-mix concrete market is projected to reach approximately USD 1,000 billion by 2027, reflecting a growing demand driven by urbanization and infrastructure development. As construction projects evolve, so too do the formulations of these cement mixes, leading to enhanced performance characteristics such as improved workability, faster setting times, and increased durability.

Major trends influencing the competitive landscape include the integration of sustainable materials in cement mixes. A survey by Grand View Research highlights that eco-friendly mixes, formulated with recycled materials and lower carbon footprints, are gaining traction among both consumers and contractors. This shift towards sustainability not only meets regulatory requirements but also aligns with the broader industry goal of reducing environmental impact. As construction professionals seek efficient solutions, the emphasis on quality, innovation, and environmental responsibility will define the top brands in ready-to-use cement mixes for 2025.

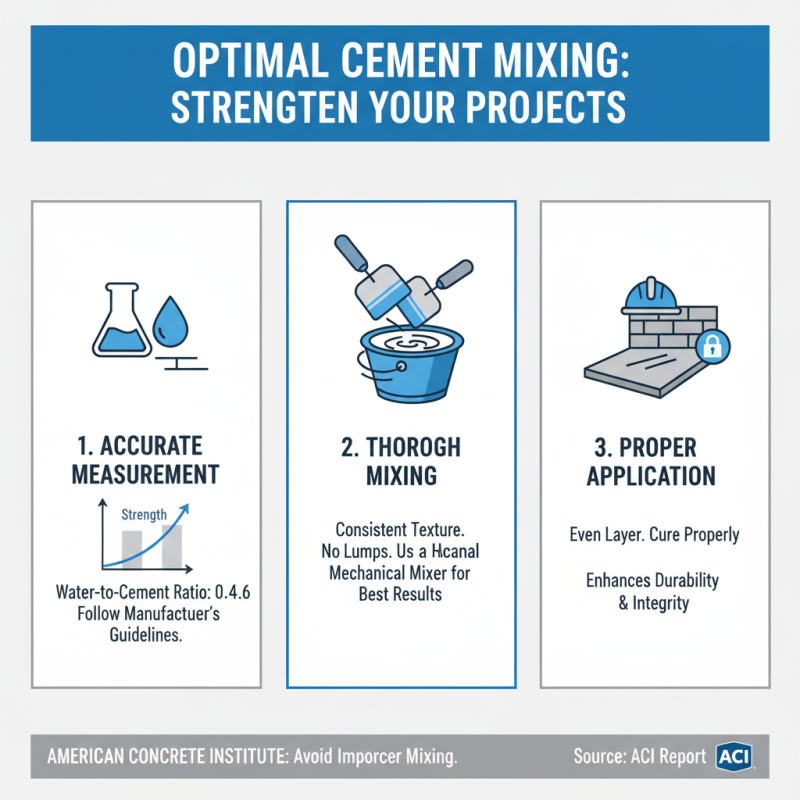

When it comes to using ready-to-use cement mixes, understanding the best practices for mixing and application can significantly enhance the durability and strength of your projects. According to a report by the American Concrete Institute, improper mixing can lead to inconsistencies that may compromise the structural integrity of concrete. For optimal results, it is essential to accurately measure water and mix components, adhering to the manufacturer’s guidelines to achieve the correct water-to-cement ratio. This ratio typically ranges between 0.4 to 0.6, depending on the specific use case, ensuring the cement achieves the desired hydration levels without becoming overly diluted.

Moreover, the application process plays a crucial role in the final quality of the cement mix. The National Ready Mixed Concrete Association emphasizes the importance of preparing the substrate to ensure adherence and prevent issues such as cracking or lifting. Techniques such as dampening the surface before application can prevent the substrate from absorbing water too quickly, which may lead to a poor bond. As recommended in various industry studies, using proper tools and techniques – such as troweling and leveling – can also aid in obtaining a smoother finish that is resistant to wear and tear. Taking these considerations into account will lead to more successful and efficient project outcomes.