Using a concrete pour calculator can transform your concrete project estimating process. Experts recommend this tool for improved accuracy. John Smith, a concrete specialist, once stated, "Accurate calculations save time and money on any project."

Estimation can be tricky, especially for large projects. Sometimes, even experienced contractors overlook details. A concrete pour calculator accounts for complexities like depth and width. This ensures your calculations are on point. Missing these factors can lead to concrete shortages or excess. Both scenarios can inflate costs and extend timelines.

Working with a concrete pour calculator brings clarity. It allows for adjustments based on specific needs. However, reliance on it requires careful input. An incorrect dimension can skew results. Thus, reflective practices in checking measurements are crucial. Knowing how to use this calculator effectively can lead to successful projects.

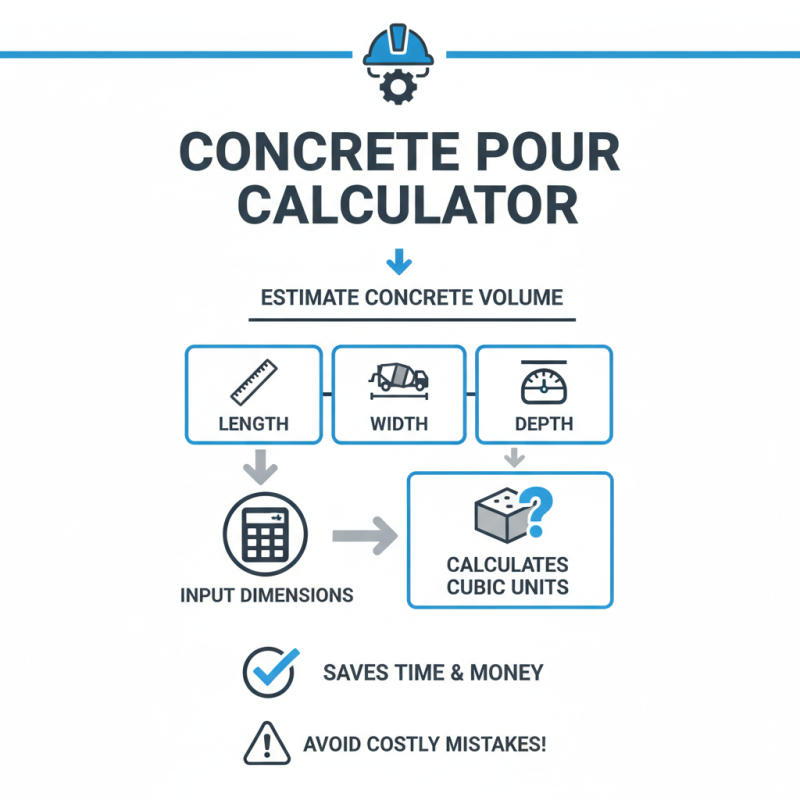

Concrete pour calculators are valuable tools for anyone involved in construction. These calculators help you estimate the volume of concrete needed for your project. You input dimensions such as length, width, and depth. The calculator does the rest. It’s straightforward yet easy to make a mistake.

When using a concrete pour calculator, ensure your measurements are precise. Measure twice, or even thrice, if needed. Mistakes in measuring can lead to overspending or underestimating. Always consider the formwork and any potential waste. Concrete can be unforgiving; wasting it could inflate costs.

Tip: Always account for a little extra material. Pouring will often create spillage or uneven surfaces that need correction. A small buffer can save you trips to the supplier. Another way to improve accuracy is to double-check your calculator's results. It’s a simple step, but it can prevent costly errors.

Accurate concrete estimations are crucial in construction projects. Even a minor miscalculation can lead to wasted resources and increased costs. Therefore, understanding the value of precision is essential. A small error in measurements can impact the entire project timeline and budget.

Using a concrete pour calculator helps mitigate such risks. It assists in determining the exact amount needed for your project. When using one, always double-check your dimensions. Measure length, width, and depth carefully. A simple misstep in measurement can result in significant discrepancies.

Tip: When inputting data into the calculator, round up small decimals. This provides a buffer and reduces the chances of running short on concrete. Also, consider ordering a bit extra to cover spills or mistakes during the pour. Remember, it's easier to have leftovers than to pour and find you are short.

| Dimension (ft) | Volume (cubic yards) | Weight (lbs) | Estimated Cost ($) |

|---|---|---|---|

| 10 x 10 x 0.5 | 1.85 | 4,090 | 150 |

| 15 x 10 x 0.5 | 2.78 | 6,110 | 210 |

| 12 x 12 x 0.5 | 2.67 | 5,880 | 200 |

| 20 x 10 x 0.5 | 3.70 | 8,150 | 250 |

| 25 x 10 x 0.5 | 4.63 | 10,250 | 300 |

Using a concrete pour calculator can seem daunting at first, but it simplifies complex calculations. Begin by finding the area you need to fill. This may be a slab, a foundation, or a driveway. Break the area into manageable shapes, such as rectangles or circles. Measure the dimensions accurately. For instance, an 8x10-foot slab requires precise calculations for estimating the volume and cost.

Once the area is defined, input the measurements into the calculator. The basic formula for volume is length times width times depth. For a slab, if the depth is 4 inches, convert this to feet. This gives you 0.33 feet. Multiply 8 by 10 by 0.33. You’ll find the total volume required is approximately 26.4 cubic feet. In industry terms, one cubic yard of concrete covers about 81 square feet at a 4-inch depth.

Remember that factors like waste and spillage affect your final needs. It's prudent to add 10% more concrete to your calculations for unexpected problems. Industry reports recommend tracking these extras carefully. Accurate estimations prevent over-ordering, which can strain your budget. It’s essential not to overlook these potential miscalculations. Always double-check your numbers. Concrete work is precise; even slight errors can affect your project significantly.

This bar chart illustrates the estimated concrete volume required for various types of construction projects based on common dimensions.

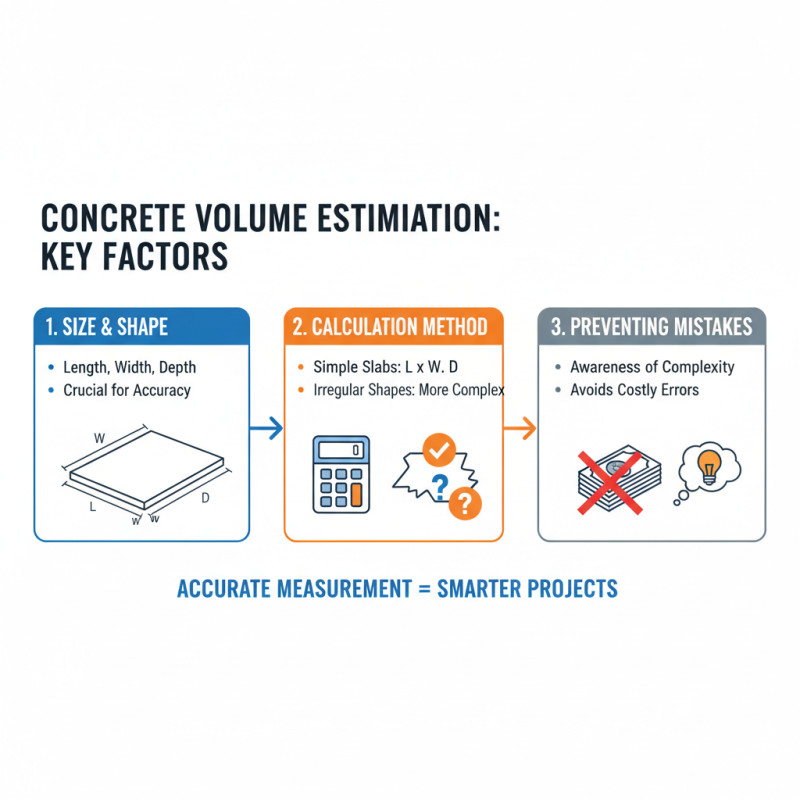

When estimating concrete volume, several key factors come into play. The size and shape of the area play a significant role. Measuring the length, width, and depth accurately is crucial. For typical slabs, a simple calculation works. However, irregular shapes can complicate matters. Awareness of this complexity prevents costly mistakes.

Consider the type of concrete needed. Different mixes might be necessary for specific applications. For instance, decorative concrete or high-strength varieties require different considerations. A report from the American Concrete Institute highlights that a standard concrete mix has a compressive strength of 4,000 psi, suitable for most residential applications. Knowing your project's requirements is essential for effective estimation.

Tips: Always account for waste. Generally, plan for an extra 10% to 15% of concrete for spillage and over-excavation. Be aware of environmental conditions too. Hot weather can increase evaporation and affect concrete consistency. Similarly, cold temperatures can lengthen curing time. If these factors aren’t considered, they may derail timelines and budgets. Keep these aspects in mind for accurate results.

Using a concrete pour calculator can save time and resources, but mistakes are common. Many users underestimate the importance of accurate measurements. A small discrepancy can lead to significant waste. According to industry reports, improper estimations can cause up to 15% more concrete to be ordered. This can inflate costs unnecessarily.

Another common error is not factoring in the depth of the pour. Many calculators require inputs for area and depth. Neglecting depth can lead to ordering too little or too much concrete. This oversight can cause delays and additional labor costs. Research shows that around 30% of concrete jobs suffer due to miscalculations in depth.

It's easy to overlook the type of mix being used. Different projects require different mixes. Using the wrong specification can compromise strength and durability. A report from the American Concrete Institute states that over 25% of projects see performance issues from improper mix choices. Always double-check your inputs. Don't rush this step; precision is crucial in getting it right.